|

Statoil begins installation work

on Asgard subsea compression modules

June 9, 2015

+ + + Statoil ASA has started installation of the modules comprising

the subsea gas compression plant for Asgard field in the Norwegian Sea. A

total of 22 modules will be installed and connected, forming two

1,500-tonne compressor trains.

The modules over the summer will be laid in place in a large subsea frame

that was installed 2 years ago (OGJ Online, June 13, 2013). The newly

rebuilt North Sea Giant vessel is carrying out installation work.

The modules comprising plant vary in size, with the smallest installed via

the vessel’s “moonpool,” a large opening in the bottom of the hull through

which modules weighing as much as 70 tonnes are lowered.

The larger

modules are installed by the North Sea Giant’s crane system, which has

been modified to incorporate a special handling system. The system is

designed to carry up to 420 tonnes and operate in up to 9-m-high waves.

Each module is guided into place with a remotely operate underwater

vehicle and cables.

All modules are provisionally stored at Vestbase in Kristiansund, Norway,

where they’re shipped out following commissioning and testing in Egersund.

Statoil notes that the installation sequence has been planned so that

start-up work can be carried out on the first compressor train while

installation work continues on modules for the second train.

Conducted in 300 m of water, the project will result in additional

production of 282 million bbl from the field, the company says. Last year,

a contract was given to Technip SA for intervention services on the

compression stations (OGJ Online, Feb. 11, 2014).

Source: Statoil - www.statoil.com

Published by Oil & Gas Journal

First Åsgard subsea compression kit heads to seafloor

June 09, 2015 + + + The North Sea Giant vessel has begun

offshore installation of the modules for the Åsgard subsea gas compression

project in the Norwegian Sea. This is designed to extract a further 282

MMbbl from the Åsgard field.

According to operator Statoil, 22 modules will be installed and connected

at a water depth of 300 m (984 ft) to form two identical compressor

trains, each weighing 1,500 metric tons (1,653 tons). They will be housed

in a large subsea frame installed on the seafloor in summer 2013.

All the modules are being shipped from Vestbase in Kristiansund, having

undergone commissioning and testing in Egersund. They vary in size. The

smallest modules – up to a maximum weight of 70 metric tons (77 tons) –

are being lowered through the vessel’s moonpool. According to operator Statoil, 22 modules will be installed and connected

at a water depth of 300 m (984 ft) to form two identical compressor

trains, each weighing 1,500 metric tons (1,653 tons). They will be housed

in a large subsea frame installed on the seafloor in summer 2013.

All the modules are being shipped from Vestbase in Kristiansund, having

undergone commissioning and testing in Egersund. They vary in size. The

smallest modules – up to a maximum weight of 70 metric tons (77 tons) –

are being lowered through the vessel’s moonpool.

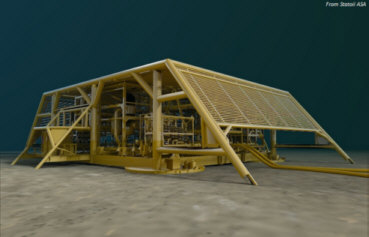

A special handling system makes the installation

work more efficient on the Åsgard field. (Photo courtesy Statoil)

Larger modules will be installed using the ship’s crane handling system

which can lift loads of up to 420 metric tons (463 tons) and which can

operate in waves up to 9 m (30 ft) high. In this case, the modules are

guided into position subsea via an ROV and cables.

Installation sequence has been planned to allow start-up work to be

performed on the first compressor train while installation of modules for

train 2 continues.

Source Statoil -

www.statoil.com

Published by Offshore

Magazine

|

Worldwide more than

100,000 paid subscriptions

| Since May 2015 OG&PE (Oil, Gas &

Petrochem Equipment) is published as part of the OIL & GAS

JOURNAL to serve a consolidated monthly audience of 135,000 oil

and gas professionals worldwide -

read more |

Worldwide

more than 48,000 subscriptions -

100% one-year direct request

qualification

'What's New' in Upstream, Midstream and

Downstream Products & Services. Circulation 37,000

PennWell

Petroleum Group:

Oil & Gas Journal

Oil & Gas Journal Russia

OGJ_eNewsletter

OGJ-Website-Statistics

Oil, Gas & Petrochem Equipment

Offshore Magazine

Offshore

Russia

Offshore eNewsletter

Offshore

Website Statistics

Oil & Gas Financial Journal

+ + +

For more information, media

kits or

sample copies please contact

Andreas

Sicking

+49 (0)2903-338570

wilhelms@pennwell.com

www.sicking.de

|

According to operator Statoil, 22 modules will be installed and connected

at a water depth of 300 m (984 ft) to form two identical compressor

trains, each weighing 1,500 metric tons (1,653 tons). They will be housed

in a large subsea frame installed on the seafloor in summer 2013.

All the modules are being shipped from Vestbase in Kristiansund, having

undergone commissioning and testing in Egersund. They vary in size. The

smallest modules – up to a maximum weight of 70 metric tons (77 tons) –

are being lowered through the vessel’s moonpool.

According to operator Statoil, 22 modules will be installed and connected

at a water depth of 300 m (984 ft) to form two identical compressor

trains, each weighing 1,500 metric tons (1,653 tons). They will be housed

in a large subsea frame installed on the seafloor in summer 2013.

All the modules are being shipped from Vestbase in Kristiansund, having

undergone commissioning and testing in Egersund. They vary in size. The

smallest modules – up to a maximum weight of 70 metric tons (77 tons) –

are being lowered through the vessel’s moonpool.