|

Shell captures CO2 with MAN integrally-geared centrifugal compressor

MAN Diesel & Turbo Berlin provides compressor technology

for a Canadian Carbon Capture and Storage Project

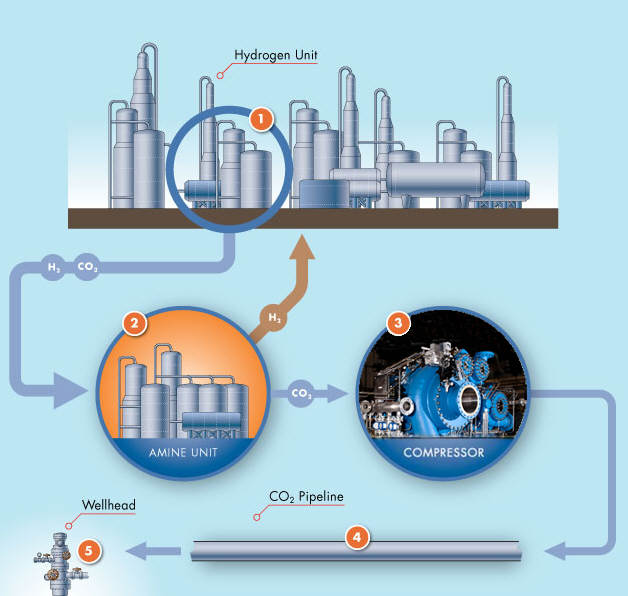

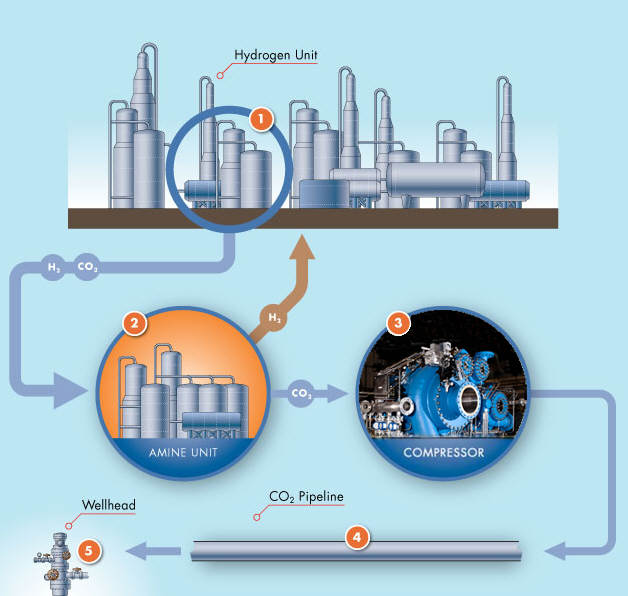

MAN Diesel & Turbo (MDT) is providing the compressor technology for Shell Canada’s Quest Carbon Capture and Storage (CCS) Project, located in Alberta, Canada.. Quest will be the world’s first commercial-scale CCS project to tackle carbon emissions in an oil sand operation. Quest will capture more than one million tonnes per year of CO2 from its Scotford Upgrader and permanently store it deep underground at an injection site north of the facility. Quest will begin injecting CO2 underground in 2015. Shell ordered a RG-type integrally-geared centrifugal compressor from MDT for delivery in 2013.

“Having won the order for engineering in 2011, the supply contract has now been signed”, says bid manager Christof Hüls. MDT Berlin will construct and hand over this type RG90-8 frame size for the first time. Four pinions are engaged with a different gear ratio, thus leading to diverse rotating speeds. Each pinion mounts two impellers in a back-to-back arrangement. They are compressing the CO2 in eight stages to a discharge pressure of 130 bar. This integrally geared centrifugal compressor handles 80,000 cubic meters of CO2 per hour. It will be constructed of familiar components which have proved reliable in different frame sizes over many years.

The discharge pressure of 130 bar is sufficient to send the compressed CO2 about 60 kilometres via an underground pipeline to a wellhead, as well as injecting the dense phase CO2 2.3 kilometres below the surface into a saline rock formation for permanent storage.

The CCS technology is regarded as important technology to help combat climate change by many industrial countries and can be applied broadly across a number of industrial applications including gas and coal-fired power plants. “MAN Diesel & Turbo is gaining further experience and competence in this area through Shell’s order”, says Ulrich Mudrack, head of the Refineries and Hydrocarbon Processing department of MDT in Berlin.

Early investments by MDT in research into CO2 applications with integrally-geared centrifugal compressors are now paying off. Already in 1999, MDT’s Berlin site delivered two RG high pressure compressors to the Dakota Gasification Corporation. These compressors have been in service to deliver CO2 for the production of synthetic gas from coal in North Dakota (USA) since the turn of the century.

“Our long-term experience and the proven reliability of our integrally-geared centrifugal compressors for use with CO2 have become an important reference attracting international attention”, reports Christof Hüls. Ulrich Mudrack adds: “Including Shell’s Quest project all our global orders for CO2 compression for Enhanced Oil Recovery (EOR) and Carbon Capture and Storage (CCS) have been won in the last 18 months. This means we are steadily consolidating our technology leadership position.”

Caption: The “Quest” Carbon Capture and Storage process: (1) The Hydrogen Unit produces hydrogen for the conversion of bitumen to synthetic crude oil. (2) The CO2 is removed from the “syngas” by contacting it with activated amine. Afterwards the CO2 is separated from the amine. (3) The purified CO2 stream is then compressed by a MAN Diesel & Turbo RG90-8 type compressor in eight stages to a discharge pressure of 130 bar. (4) This is sufficient to send the compressed CO2 about 60 kilometres via an underground pipeline to a wellhead. (5) The dense phase CO2 is injected 2.3 kilometres below the surface into a saline rock formation for permanent storage.

Image courtesy of Shell Canada Ltd.

Source:

Monika Koenig,

MAN

Diesel & Turbo SE

www.mandieselturbo.com

|

PennEnergy

Weekly Newscast

.

+

+ Media Links + +

Oil

& Gas Journal:

Worldwide more than 100,000

paid subscriptions

Learn

more

For more information, media details or

sample copies please contact

wilhelms@pennwell.com

www.sicking.de

|