|

Ecom Mobile Safety

Enhancing RFID to improve safety and productivity in

potentially hazardous areas

2014, Jan. 26 + + + How the

recent introduction of the innovative UNI900 UHF RFID reader/writer for

ecom’s i.roc® Ci70 -Ex handheld computer (PDA) enables new levels of

safety and productivity in potentially hazardous locations.

As

organizations look for new ways to improve operational efficiency and

workforce productivity without compromising on safety, the use of RFID

technology within the workplace is becoming more prevalent to quickly and

accurately identify equipment, tools, parts/spares, locations, and even

people. As

organizations look for new ways to improve operational efficiency and

workforce productivity without compromising on safety, the use of RFID

technology within the workplace is becoming more prevalent to quickly and

accurately identify equipment, tools, parts/spares, locations, and even

people.

Also, UHF RFID technology advancements over the past few

years to improve performance in/on metal, improve ruggedness, reduce the

tag size, and increase on-board memory size has brought this technology

firmly in the frame for hazardous area projects. In fact, many see this

technology as the future automated identification standard within

hazardous areas since it offers more flexibility for the lifetime tracking

of equipment both within a site and across supply chains.

However,

in hazardous areas, some users still struggle with PDA devices which are

large and poorly balanced, with protruding “bolt-on” UHF RFID readers and

antennae which are difficult to use, awkward to carry, and can easily be

snagged on plant equipment and infrastructure such as ladders –

potentially creating a safety incident.

And, over the lifetime of

an RFID-tagged item of equipment, the tag needs to be read from close

range when the equipment is inspected and from long range when the

equipment is moved. Until now, the use of UHF RFID tags on adjacent

equipment has carried the risk that the wrong equipment was scanned, and

the inspection details were recorded against the wrong item of equipment.

Reading smaller RFID tags which are embedded in metal or mounted on metal

has also been a challenge.

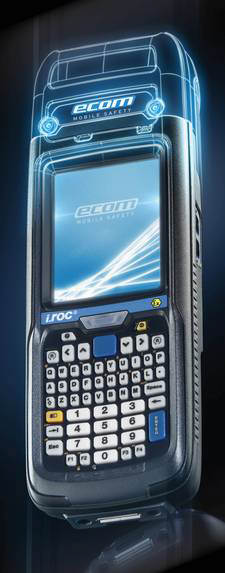

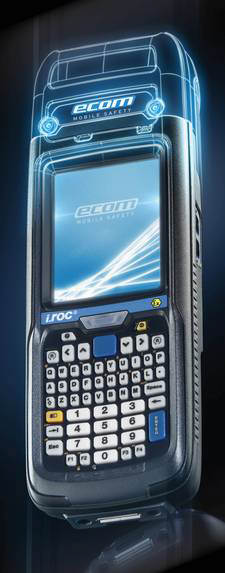

With the recent introduction of the

intrinsically-safe UNI900 UHF RFID reader/writer for ecom’s i.roc® Ci70

-Ex, these concerns can now be relegated to the past. Based on ecom’s 12

years of experience delivering replaceable RFID heads, the UNI900 has

designed-in protection to operate safely in hazardous areas. And, the

unique flexibility of the UNI900 to read UHF RFID tags from both close

range and long range means you can use it without restriction for any

application. Improved antenna performance also allows reading of small

RFID tags embedded-in and mounted-on metal.

Connected to the i.roc®

Ci70 -Ex, PDA as an integrated head module, the UNI900 head retains the

same streamlined and well-balanced features of the i.roc® Ci70 -Ex,

avoiding the use of any protruding “bolt-on” modules. Setup of new devices

is also fast and simple using the automated ‘Scan N Go’ capability.

For existing Ci70 -Ex users, the UNI900 head can be easily retrofitted

onto your existing devices – giving you the future proofing you expected

when you purchased your device. There is no need to buy a new Ci70 -Ex

PDA, saving you time and money.

Typical applications for this

device include plant audits/surveys, equipment/tool management, field

inventory management, supply chain logistics, operator rounds,

inspection/maintenance/repair, emergency mustering, and plant security

checks.

And, the benefits include: reduced user fatigue and

improved user experience; improved real-time visibility and control of

containers, equipment and tools; improved accuracy of the item’s

cradle-to-grave history; reduced safety non-compliance risk; improved

decision making and accountability; and higher profitability.

ecom

instruments GmbH

Source: Christian Uhl - Vice President Marketing

http://www.ecom-ex.com

See also:

Avoiding inefficient and unsafe working practices in potentially

hazardous areas

|

Worldwide more than

90,000 paid subscriptions

Worldwide

more than 48,000 subscriptions -

100% one-year direct request

qualification

'What's New' in Upstream, Midstream and

Downstream Products & Services. Circulation 37,000

PennWell

Petroleum Group:

Oil & Gas Journal

Oil & Gas Journal Russia

OGJ_eNewsletter

OGJ-Website-Statistics

Oil, Gas & Petrochem Equipment

Offshore Magazine

Offshore

Russia

Offshore eNewsletter

Offshore

Website Statistics

Oil & Gas Financial Journal

+ + +

For more information, media

kits or

sample copies please contact

Andreas

Sicking

+49 (0)2903-338570

wilhelms@pennwell.com

www.sicking.de

|